The automatic device used to control journal-box shift from the axle neck is a subsystem of the "Automated diagnostic system for the measurement of geometrical parameters of car wheelsets.”

Intended application

Detection of roll journals of freight cars of a moving train that have end fixture destruction and a shift of the journal body from the axle neck (without heating of the axle box), registration of such journals and prompt transfer of the information obtained to the nearest maintenance depot.

Distinguishing feature

A distinguishing feature of the device is the non-contact measurement of wheelset geometrical parameters of the moving railway equipment at speeds up to 60 km/h in different climatic conditions.

Application of the system makes it possible to increase the reliability of the rolling stock and to eliminate to the greatest possible effect the likelihood of accidents on the railway caused by defects of wheel pairs.

Principle of operation

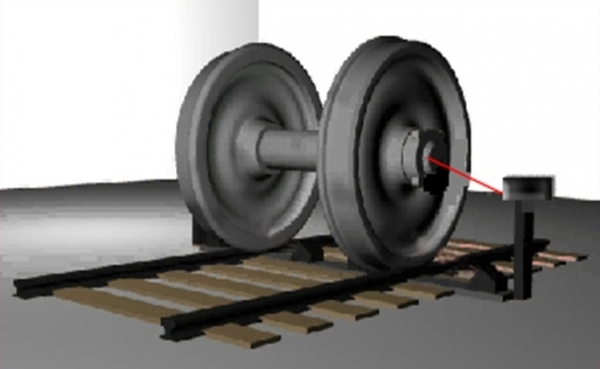

The engineering solution to the problem of monitoring box shift is based on two fast-response PSD-based triangulation sensors. Either sensor is designed to measure distance to the surface of box main covers. Subsequent co-processing of signals from both sensors determines distance between the box main covers and so makes it possible to register deviations of the parameter from the acceptable value. To get detailed information about the defective box (if the deviation exceeds the acceptable value) gage side triangulation sensors are actuated to measure the distance to the inner edges of the wheelset.

Measurement results for wheelsets of the passing train are stored on the computer and further transmitted to the automatic control system of the maintenance depot using TCP/IP protocol.

|

Principle of measurement

|

|

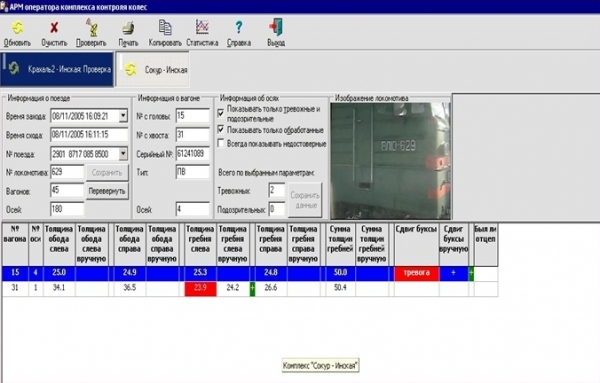

Operator’s workstation

|

Technical information

-

Wheelset linear speed at measuring - 10 to 60 kph.

-

Power consumption 500 W.

System components

-

Trackside assets (mounted on the roadbed);

-

Station equipment (in a heated room);

-

A computer with pre-installed workstation software for displaying inspection results;

-

Control program.