The system for diagnosing wheel thread defects is a subsystem of "Automated diagnostic system for the measurement of geometrical parameters of wheelsets.”

Intended application

Detection of such defects as slid flat, weld-on deposit and uneven wear during train movement, their registration and prompt transfer of alarm information to the nearest maintenance depot.

Distinctive feature

A distinctive feature is non-contact measurement of rolling stock wheelset defects during train movement at the speeds up to 60 km/h in various climatic conditions.

Application of the system makes it possible to increase reliability of the rolling stock and eliminate to the greatest possible degree the possibility of accidents on the railway caused by defects of wheelsets.

|

Exterior view of the subsystem

|

|

Sensor

|

Principle of operation

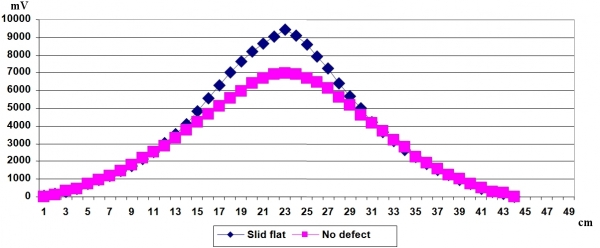

The system was designed based on inductive fast-response proximity sensors. Total number of sensors – 32 (16 sensors per each side). The sensors are fixed on the rail at the distance of 30 cm from each other. Each sensor is an inductive four-coil bridge with a ferrite core and power supply from excitation winding (frequency of 100 kHz). In the initial condition, the AC output signal is equal to zero. A metal object approaching to the sensor results in changes in inductance of the respective pair of coils, which leads to bridge unbalance and generates an output AC signal, the value of which depends on the distance between the sensor and the wheel flange.

Technical characteristics

Measurement of linear speed of wheelset during train movement ………..............from 10 up to 60 km/h.

Operating temperature range…………………………………………………...............from - 50 up to +50°C.

Power supply ……………………………………………………………………………. ……..............…220 V.

Power consumption ……………………………………………………………………………................500 W.

Configuration of the system

Trackside equipment (is mounted on railroad tracks, no earthwork in the road prism is required);

Tower equipment (is installed in a heated room, in the rack of the automated Kompleks);

Supervising software (is installed in the supervisory computer of the Kompleks).